wholesale square nuts carbon steel stainless steel and can custom size

Read More: Catalog nuts

The use of square nuts can reduce looseness or vibration between parts and improve the efficiency and stability of the entire equipment.

What is a nut square used for?

nut square is a threaded connection commonly used in fastening connections of mechanical equipment. Its main function is to closely connect two or more parts to form a whole by cooperating with threaded bearings to achieve the effect of fixing, supporting or transmitting force. The use of square nuts can reduce looseness or vibration between parts and improve the efficiency and stability of the entire equipment.

Are square nuts still used?

yes,such as automobiles, motorcycles, bicycles, construction, woodworking, metal processing and other fields.

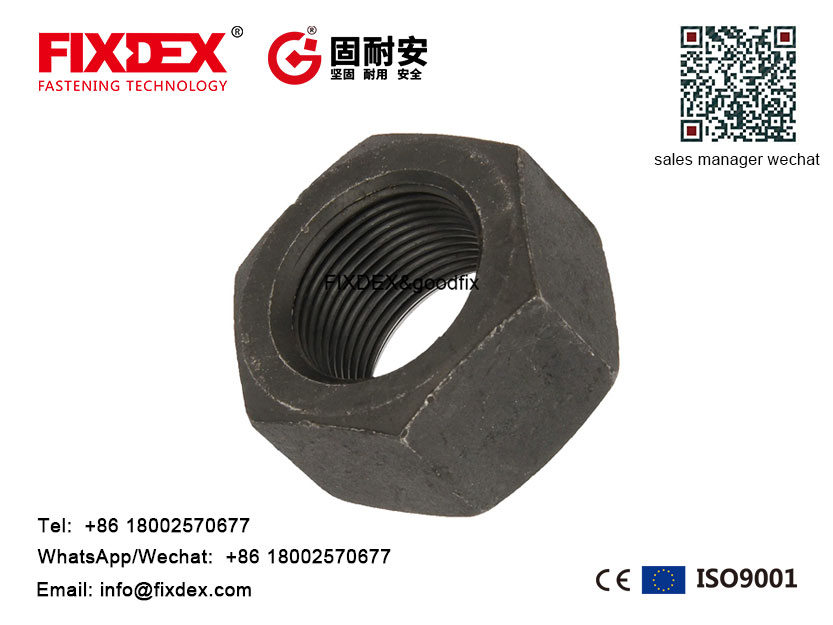

What is the difference between a square nut and a hexagonal nut?

1. Square Nut Fasteners Structural design

There are certain structural differences between square nuts and hex nuts. Square weld nuts are usually square or rectangular in shape and have a shorter thread length to make the structure more compact. The hexagonal welding nut is a hexagonal prism shape, and the thread length is usually longer, which can provide better tightening effect. Therefore, when a more compact structure is required, the square welding nut can be selected, and when a better tightening effect is required, the hexagonal nut can be selected.

2. Square Nut Hardware Installation method

There are also differences in how square nuts and hexagon nuts are installed. Square weld nuts typically require a smaller weld area to secure, while hex weld nuts require a larger weld area. Therefore, when the installation space is small, you can choose square welding nuts, and when the installation space is larger, you can choose hexagonal welding nuts.

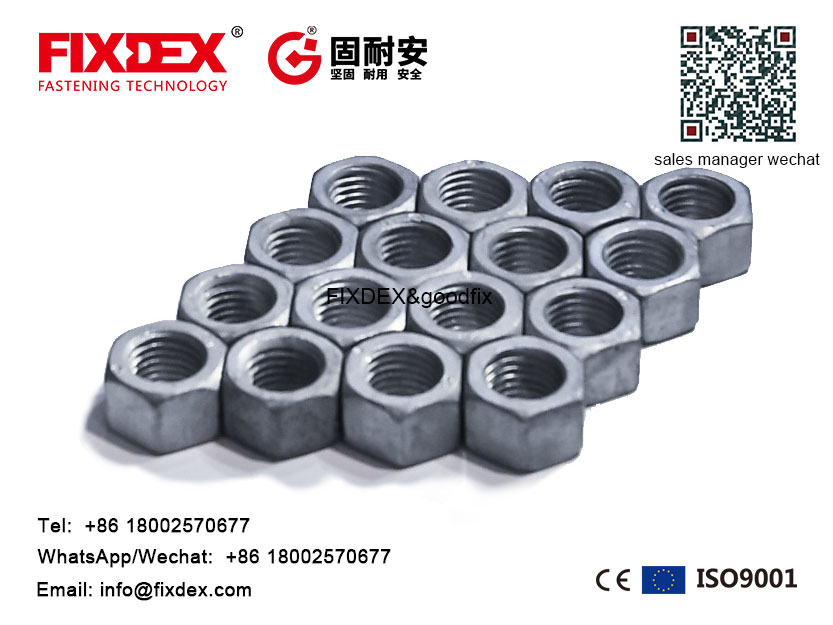

3. SQUARE NUT DIN557 Carrying capacity

There are also certain differences in load-bearing capacity between square welding nuts and hexagonal welding nuts. The hexagonal structure of the hexagonal welding nut provides better force transmission and therefore has a higher load-bearing capacity. The square welding nut has a relatively poor load-bearing capacity due to its small welding surface. Therefore, hexagonal welding nuts can be selected where higher load-bearing capacity is required.

4. SQUARE NUTs Service life

There is also a certain difference in the service life of square welding nuts and hexagonal welding nuts. The structure of the hexagonal welding nut allows the force to be more evenly distributed on the welding surface, so its service life is relatively long. The square welding nut has a smaller welding surface and is easily affected, resulting in a shortened service life. Therefore, hexagonal welding nuts can be selected when longer service life is required.

When did they use square nuts?

Square nuts are suitable for fastening connections in a variety of mechanical equipment, such as automobiles, motorcycles, bicycles, construction, woodworking, metal processing and other fields.

1. Choose square nuts of appropriate type and material, and try to avoid mixing or using inferior products.

2. Before use, clean the connection part to ensure that the threads are firm and clean.

3. Use the tools correctly and maintain appropriate strength. Do not use excessive force or apply excessive torque to avoid damaging the nuts or connectors.

4. If the square nut has been used for a period of time, please check whether there is wear or damage and replace it in time if necessary.

5. After assembly is completed, check whether the connecting parts are loose or deformed, and reinforce or replace them in time to ensure the stability and safety of the equipment.